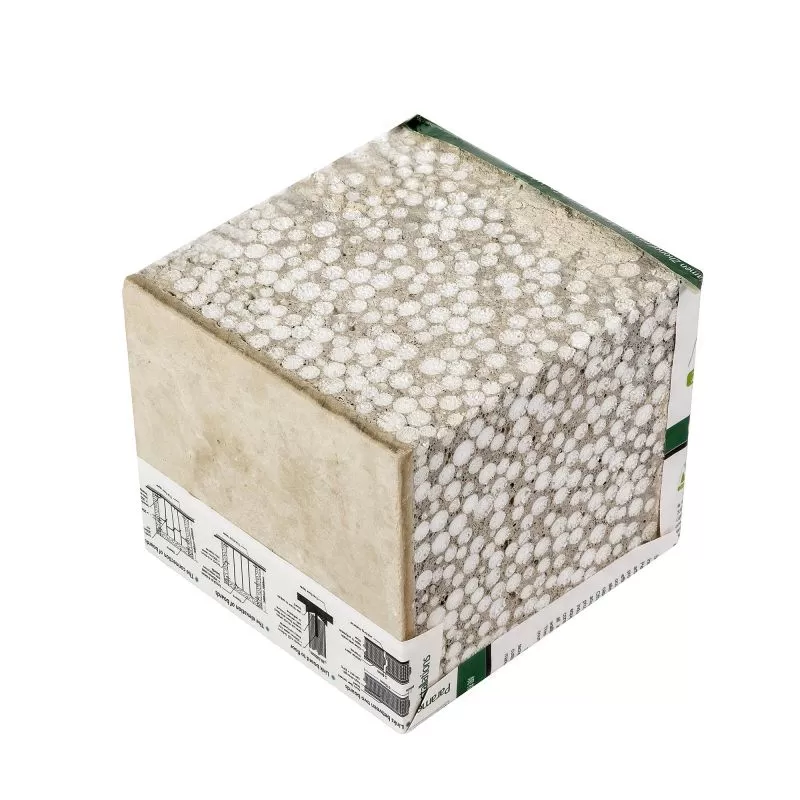

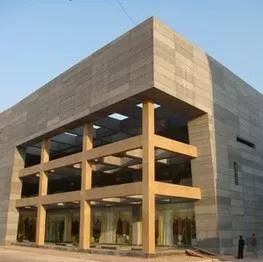

The lightweight partition board is a new type of energy-saving wall material, which is a wall material like a hollow floor.but it has a male and female groove on both sides. Simply stand up the board when installing.After the male and female troughs are coated with a small amount of caulking mortar, they can be assembled.

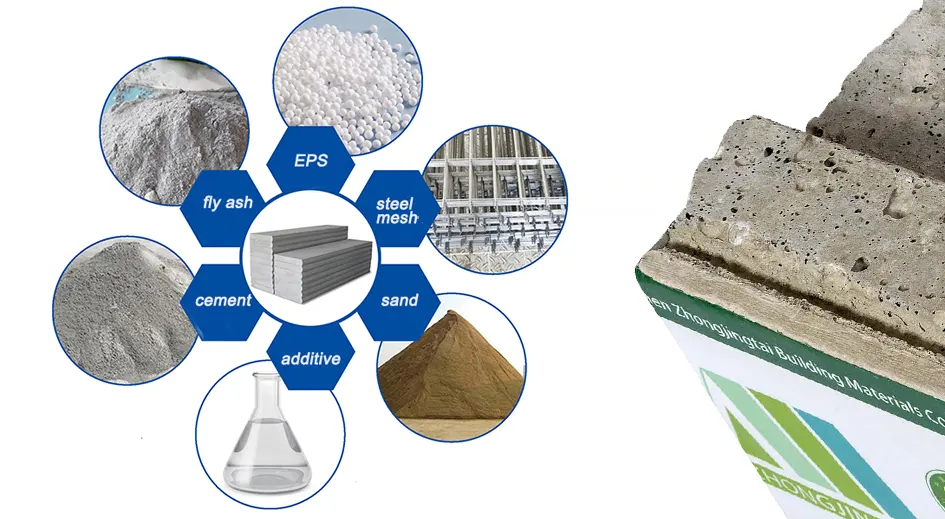

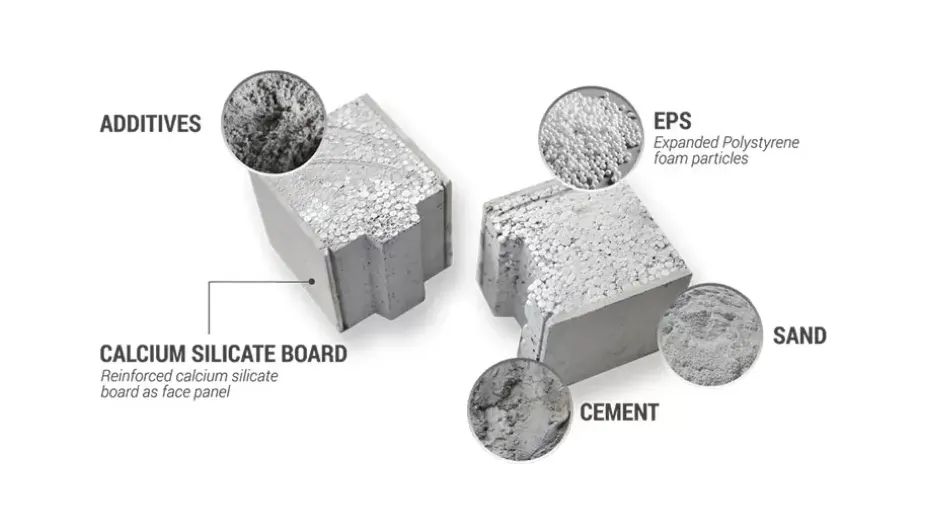

1. Light weight: The raw materials are light aggregate and fly ash. The heavy raw materials such as reinforced concrete and sandstone have the characteristics of light weight, which is only 1/16 of the quality of the brick-concrete structure, which can greatly reduce the structure of the building. Longitudinal load reduces the building's own weight and reduces the construction cost.

2. Insulation: Since the wallboard is made of polystyrene foam board as the core insulation material, the insulation performance is extremely superior to the building energy-saving design standard of the Ministry of Construction, and it ranks first in the domestic similar products.

3. Impermeability: The water absorption rate of the new wallboard is only 3.3%, which has reached the international advanced level in the same industry.

4, fire performance: the new wallboard products themselves, never burn. Experiments show that the new wall panel is an ideal fireproof material, and the fireproof capacity of the 9cm thick wall can reach more than 3 hours.

5, sound insulation function: Because the new wall panel - polystyrene is a sandwich material, it has a good sound insulation effect, the solid sound insulation is greater than 42 decibels, reaching the national industry standard.